Esperanto

Esperanto

Shqiptare

Shqiptare

Euskara

Euskara

Zulu

Zulu

Latinus

Latinus

Cymraeg

Cymraeg

தமிழ்

தமிழ்

Slovak

Slovak

Slovak

Slovak

Afrikaans

Afrikaans

NEWS

23

2025

-

04

TUP thin-wall packaging speeds up by 17%!

Author:

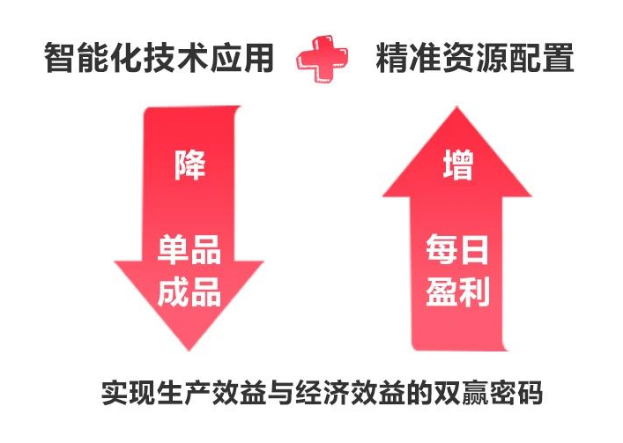

In the competitive landscape of the packaging industry's "fast turnaround, low-cost" race, TUP Taiwan Liansu's ES all-electric thin-walled high-speed packaging special machine has become a strategic engine for enterprises to break through, with its core strength of "further shortened cycle times." From exhibition sites to customer production lines, its production cycle data continues to be refreshed.

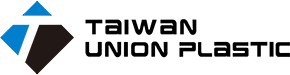

Take the 130g IML yogurt cup as an example.

TUP Taiwan Liansu has orchestrated a dramatic efficiency surge over one year:

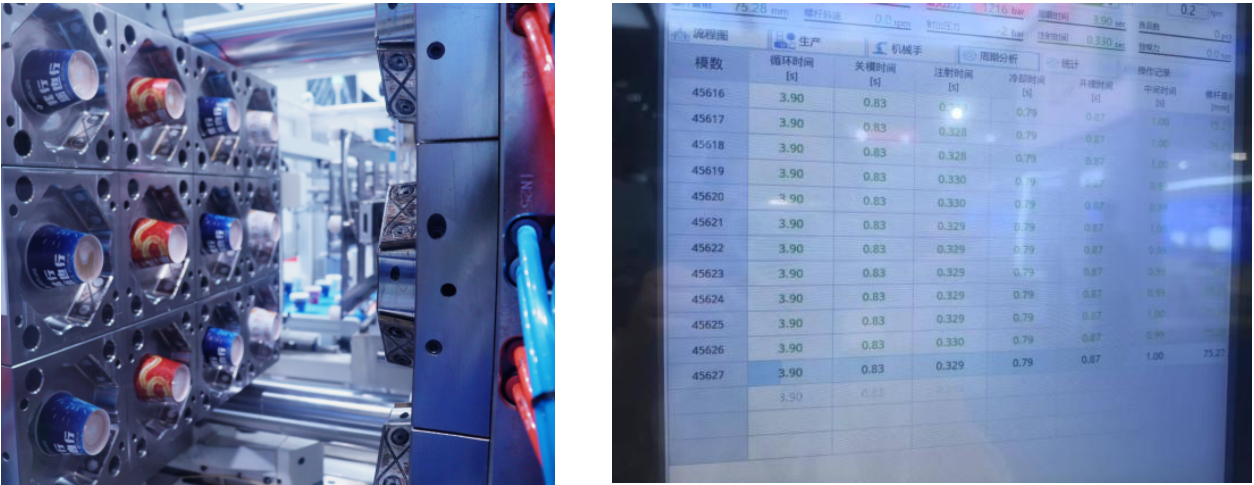

- 4.7 seconds at Chinaplas in April 2024

- 4.3 seconds at DMP Rubber & Plastic Exhibition in November 2024

- 3.9 seconds in a live demonstration in April 2025

Achieving a 17% cycle time compression.

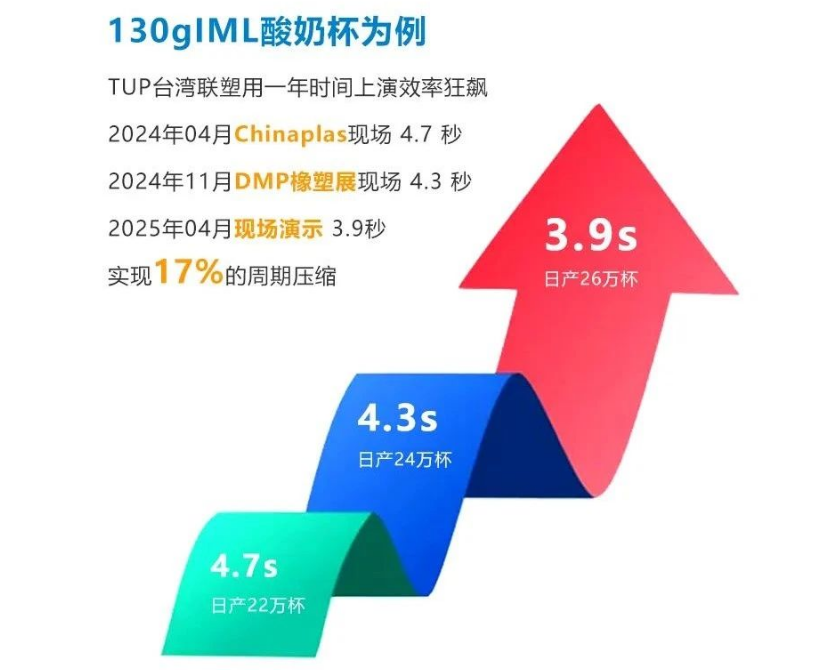

Intelligent technology application + precise resource allocation** Lower single-product costs while increasing daily profits The winning formula for achieving both production efficiency and economic benefits

This significant "plunge" in data not only represents a direct reduction in production cycle but also reflects the deep evolution of TUP's technological iteration and scenario adaptation in the injection molding industry. It has truly propelled thin-walled packaging production into a "race against every second" fast lane.

Millisecond-Level Response, Lightning Speed

In response to the stringent requirements of thin-walled packaging for "short cycles and high injection speeds," TUP's ES All-electric thin-walled high-speed packaging special machine provides a one-stop integrated solution. From product design to mold adaptation, system-level integration ensures the equipment achieves "high output from start-up."

- Extreme-speed mold opening/closing: Speed increased by 20%, effectively saving time compared to traditional equipment.

- 450mm/s ultra-high-speed injection: Specifically designed for thin-walled products with large flow length-to-thickness ratios.

- Injection compression black technology: Enhances efficiency by 10% while reducing clamping force and minimizing product deformation.

Cost Reduction, Efficiency Improvement, Multi-Scenario Adaptation

TUP supporting motion control system breaks through the barriers of thin-walled injection molding.

- Overcomes the molding challenges of ultra-high L/T ratio (flow length-to-thickness ratio) products, effectively improving product yield.

- Flexibly adapts to multi-cavity molds, rapidly responding to multi-category order demands.

- Customizes solutions for lightweight thin-walled packaging, balancing structural strength and production efficiency.

As the packaging industry enters an era of "racing against every second," TUP's All-electric injection molding machines are delivering more suitable, cost-effective, and market-competitive overall solutions with the advantages of "shorter cycles, lower costs, and higher precision." After all, in the packaging field, every second saved translates into tangible growth in profits.

Related News